From 20 June to 1 July 2022, the Department of Primary Industries and Mines (DPIM) in collaboration with the United Nations Industrial Development Organization (UNIDO) and the National Institute of Development Administration (NIDA) have organized the training program on Best Available Techniques (BAT) and Best Environmental Practices (BEP) application to scrap metal recycling industry for reduction of the Unintentional Persistence Persistent Organic Pollutants (U-POPs) under the project “Greening the Scrap Metal Value Chain through Promotion of BAT/BEP to Reduce U-POPs Releases from Recycling Facilities”. The training objective is to disseminate the knowledge and understanding about U-POPs, health, and environmental impacts, relevant laws and regulations, and management of scrap metal in the supply chain in accordance with the sound management. The Training programs module 1 to module 5 are developed for the authoritative agencies, educational institution, research institutes and NGOs.

Module I: Unintentionally-released Persistent Organic Pollutants (U-POPs) on 20 June 2022 via online ZOOM program instructed by Associate Professor Dr. Adisak Pattiya, Lecturer of Department of Mechanical Engineering. Faculty of Engineering Mahasarakham University as a speaker to 39 participants.

Module II: Policies, Laws, and Regulations on 21 June 2022 via online ZOOM program instructed by Ms. Teeraporn Wiriwutthikorn, a specialist in waste and hazardous substance management from the Pollution Control Department as a speaker to 63 participants.

Module III: Scrap Metal Industry and U-POPs Emission on 28 June 2022 via online ZOOM program instructed by Asst. Prof. Dr. Ronbunchob Apiratikul, Lecturer of the Faculty of Environmental Sciences Suan Sunandha Rajabhat University and Dr. Wareerat Akkaratham, Managing Director of Trident Steel Co., Ltd. as the speakers to 62 participants.

Module IV: Management of U-POPs in Scrap Metal Industry from 29 June to 1 July 2022 via online ZOOM program instructed by Prof. Dr. Siwat Pongpiechan Director of Disaster Prevention and Management Research and Development Center Assoc. Prof. Dr. Adisak Pattiya, Lecturer at Department of Mechanical Engineering Faculty of Engineering Mahasarakham University and Asst. Prof. Dr. Ronbunchob Apiratikul, Lecturer of the Faculty of Environmental Sciences Suan Sunandha Rajabhat University as the speakers toof 35, 36, and 28 participants respectively.

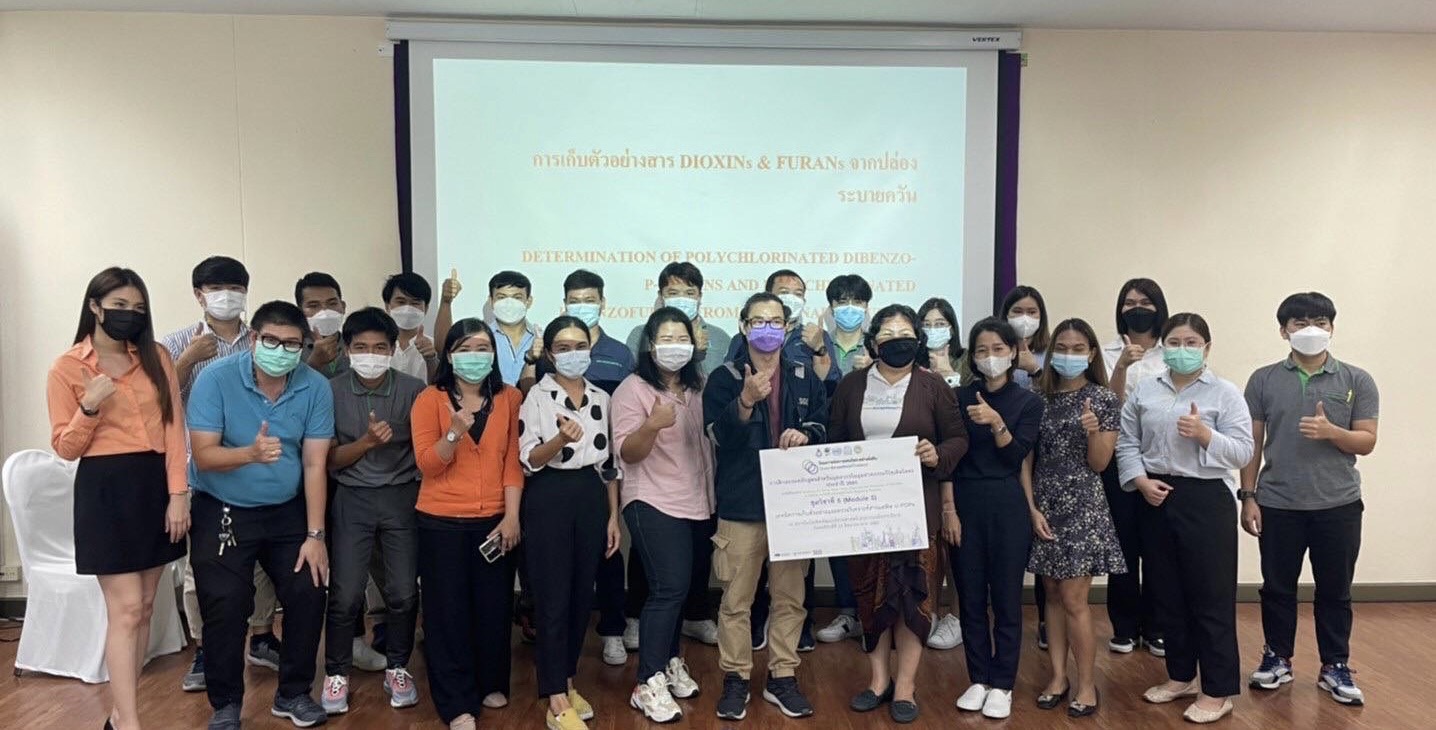

Module V: Technical Sampling and Analysis of U-POPs Industry from 22 to 24 June 2022 via online ZOOM program for Day1, onsite at Nawamin Building, National Institute of Development Administration for Day2 and visiting 2 Laboratories for Day3. This module was instructed by Prof. Dr. Siwat Pongpiechan, the Director of Disaster Prevention and Management Research and Development Center, Mr. Wisak Boonpromteerakul, representative of SGS (Thailand) Co., Ltd., Mr. Methawat Rungsiriworaphong, Environmental Officer of Department of Environmental Quality Promotion and Mr. Paitoon Nimwongcharoensuk, representative of Bara Scientific Co., Ltd. to 39, 26, 10, and 14 participants respectively.

The training participants are the representatives from various agencies, such as Department of Health, Department of International Trade Negotiation, Office of Industrial Economics Food and Drug Administration, Chachoengsao Provincial Industrial Office, Office of Natural Resources and Environment of Chachoengsao Province, Mon Nang Subdistrict Municipality in Chonburi, Thap Ma Subdistrict Municipality and Pak Nam Prasae Subdistrict Municipality in Rayong province, Chulabhorn Research Institute, Chiang Rai Rajabhat University, Mahasarakham University, Emex Association Company Limited, and Kon Chang Foi Company Limited.

The evalutation showed that participants have gained better understanding of the environmentally friendly sound management of the scrap metal recycling industrial value supply chain and awareness of the health risks from U-POPs, especially dioxins and furans. Additionally, BAT/BEP can be applied to reduce U-POPs releases from the scrap metal recycling industry and during the Q&A session various issues have been shared for fruitful discussion which allows the participants to obtain more knowledge and experience.